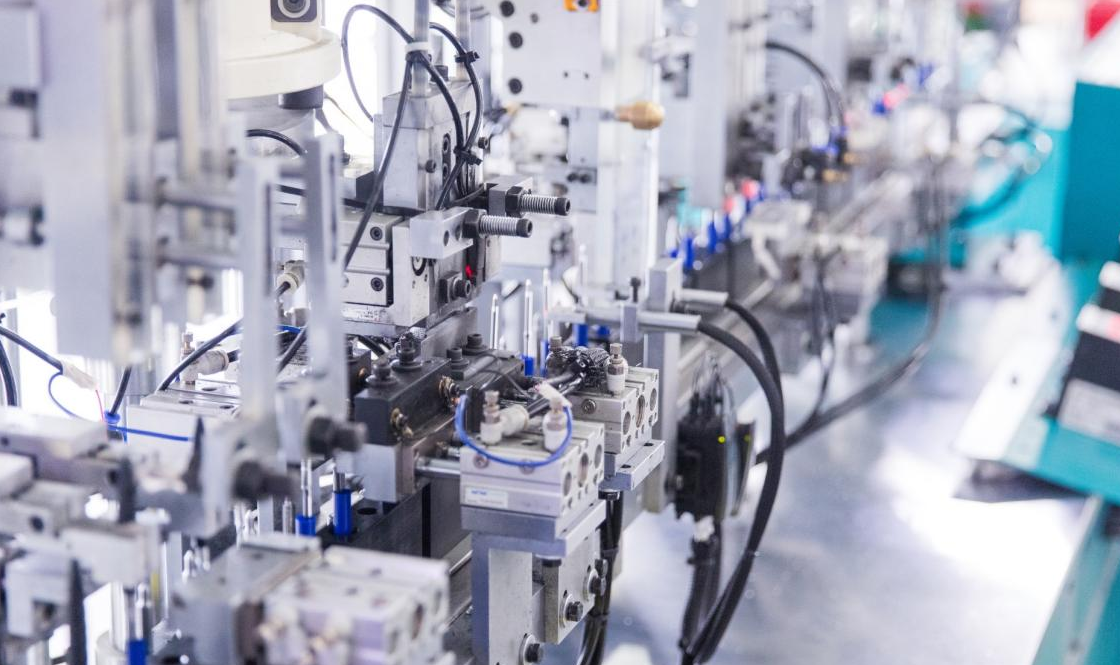

Business Challenges:

- Inability to trace the quality of raw material batches, process batches, finished product batches, and shipment batches.

- Lack of correlation between DCS data and packaging data with product data.

- Management unable to promptly identify quality issues during production.

Solution:

- Establishment of quality-related traceability information for raw material batches, domestically produced batches, finished product batches, and shipment batches.

- Implementation of automatic quality analysis and alerts to notify responsible personnel based on predefined rules.

- Collection of DCS data through OPC and correlation with production batches.

Project Benefits:

- 40% improvement in the closure rate of quality measures.

- 65% reduction in the average closure time of quality measures.

- 10% increase in the qualification rate of raw materials.

Copyright © KORISDA . All Rights Reserved